‘Lightweighting’

September 2018

Introduction

Light-weighting i.e. weight/mass reduction techniques are continually evolving in pursuit of lighter, stronger, more efficient material usage and performance. Movement requires energy so if it moves or is moved it should be ‘lightweighted’. Manufacturers seek to lighten vehicles to reduce fuel consumption / improve electric vehicle efficiency, reduce resource usage and lower manufacturing costs with CO2 reduction being a fundamental driver. These concepts are readily applicable across automotive, aviation, aerospace industries, energy harvesting and any moving part projects for example. “For every kilo of material removed from an aircraft, 100kg of jet fuel can be saved per year”.

Specification improvement

Another aspect to this initiative can be inventing a higher spec. version of the standard product — think Porsche 911/964 'Leichtbau’, Lamborghini Huracán Performante or more recent McLaren P1 GTR. McLaren's CEO Mike Flewitt calls on the priority of lightweighting albeit promoting carbon fibre (x20 more expensive than steel, x10 aluminium, heat-sensitive and difficult to recycle), but the light weight objective remains the same [Link to article on The Engineer].

Application

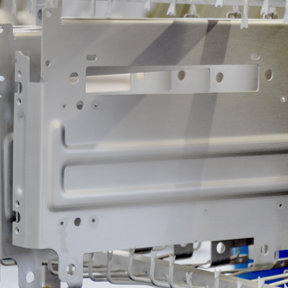

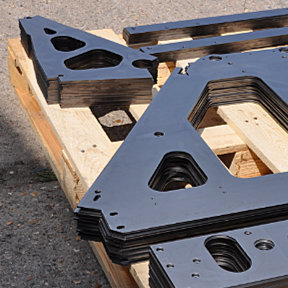

Initially one looks at the material used i.e. graded aluminium, magnesium, high-strength steel alloys, observing that stronger can also mean more brittle. Thinner grades can have wrinkle and distortion issues in the fabrication process alongside problems with potential cracking occurring during forming because of the increased press loads, plus tooling tends to wear faster and springback is more pronounced. As chassis and parts get lighter forming can be applied to build strength in to the parts, integral strength can be improved alongside light-weighting (with cut-outs) by adding additional shallow forming that improves the tensile strength.

Glenmore Hane's designers, press brake operators and quality controllers are skilled to avoid these pit-falls through our fine limit sheet metal fabrication processes and experience. Talk to our account team with their wealth of knowledge about how we can design and assist in light-weighting to get the most out of your project.

About Glenmore Hane

Glenmore Hane are fine limit sheet metal fabricators and finishers supplying customers nationwide. Specifically positioned on the M4 corridor with fantastic links to the rest of the country, Glenmore Hane design, fabricate and finish high quality sheet metal components in the UK. We are fully qualified to ISO9001:2015 management standards ensuring reliable and quality controlled production output on demand and on time. If you have a new project or existing production line, you can either send it direct through our website enquiry page and/or call us on 01753 528884 we'd be happy to take a sturdy look at it.

Glenmore Hane, August 2018

Contact: Mark Hall on 01753 528884

Next month…

What you need to know about Hexavalent Chromium