Glenmore Hane is all about fine limit sheet metal fabrication and finishing for aerospace, automotive, marine, electronic, audio visual, research, science, testing and bespoke projects in commercial, defence, medical and industrial sectors.

“The service level very good, when they say they'll deliver they do, and with the anodising plant on board it's a great fit. When we develop new products, they go the extra mile. We sell a luxury product to the rich and famous so every detail needs to be right. We demand top-end quality, the product must perform and Glenmore Hane consistently helps us achieve that”.

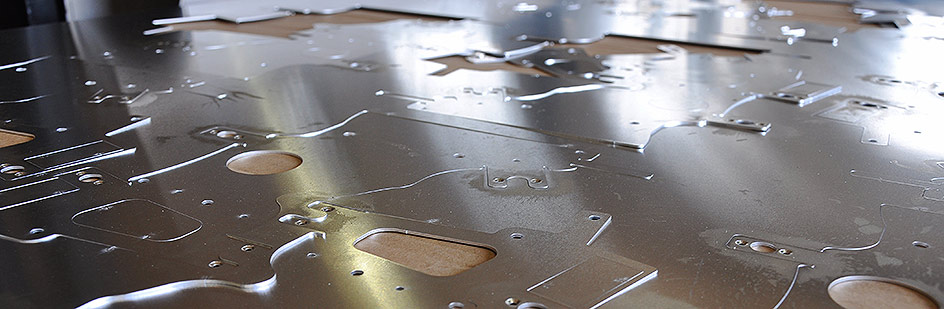

Typically we laser cut up to 5mm aluminium, 5mm stainless steel, 3mm mild steel, 2mm copper and 3mm brass. (Other thicknesses to order). We can handle up to 3x1.5m metal sheet sizes, bend 3m wide sheets, anodise items up to 2.8m long and powder-coat up to 2.2m.

We have 48 staff, across our departments starting with enquiries, design (CAD/CAM), cutting, forming, welding, fettling, inspection, pre-finish, finishing, packaging, delivery and our administration office that keeps everything organised.

Glenmore-Hane Group Ltd. came about through the merger of Glenmore Engineering Ltd., Glenmore Plating Ltd., Hane Instruments Ltd., and AA Finishers LLP on 1st June 2014. The origins of these local businesses go back to 1970's. We moved in to 20,000ft2 premises on The Slough Trading Estate, central southern England, near to the M25, on the M4 corridor. Fast forward to today and the mergers have facilitated the one-stop shop with a range of services including automated laser/punch combination production, welding, forming, priming, finishing, assembly and delivery.