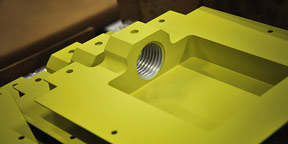

1000 brackets made in Great Britain

Wandering through Glenmore Hane from the pre-production studio, past the Amada fibre laser cutters, HG bend and fold machines with automatic tool set loader, past the trusty Promecams, graining, welding and quality control inspection office you see a lot of different sheet metal components and cases and shapes and forms. And all that before the finishing department across the courtyard where all these parts and other CNC'd and metal formed items can be cleaned, coated, primed, painted, powder coated or anodised.

This got me wondering if there is an ideal production piece? Asking around well not really, and there's no plan to specialise in left-handed coat hangers or the like, but brackets, instrument panels and such components are easy to handle, hang, stack, carry and manoeuvre in the production and finishing processes. A quick look on our Instagram feed [ instagram.com/glenmorehane ] will show you some of the typical projects we process everyday. So if it were a bracket that fits in your hand and we fabricated and finished in batches of a thousand at a time that would also mean we can deliver them in one vehicle too – and that's even more ideal.

Whilst fabricating and finishing parts, we're all about precision or fine-limit as we like to call it, sheet metal cut within ±0.02mm, bends set to within 0.25º, coat and paint applied within ±0.2mm average and surface finishes anodised within 0.025mm (25µ microns)... more info. We often fabricate projects and parts for research, science labs, defence, pharmaceutical and 'high-end' applications so adhering to strict specifications and accuracy is expected and always a (high) standard practice at Glenmore Hane.

And then there's our staff — the team that make it all happen, who individually know what they produce today represents all of us tomorrow, who strive their craft and breathe experience and skill in to their work for your bracket, box, case, component, panel, part and widget for whatever it needs to do.

Made in Great Britain, in Slough and proudly done.

What do you ideally need?

About us

Glenmore Hane remains committed to provide fine-limit sheet metal services by highly experienced and knowledgeable staff who can advise on production techniques as well as environmentally sound solutions. We fully qualified to ISO9001:2015 standards ensuring reliable and quality-controlled production on demand and on time. If you need precision sheet-metal protoypes, short or batch-run sheet metal fabrication and/or finishing – either send it direct through our website enquiry form, or telephone 01753 528884