What is the 'fine-limit' in precision sheet metal fabrication?

We can cut sheet metal within ±0.02mm and set a bend to within 0.25º. For most sheet metal components, boxes, chassis and part applications this is precise. Across most project batches, after finishing including coating and paint we'll average ±0.2mm as standard, anodised surface finishes are accurate within 0.025mm (25µ microns). For specialist projects we can get tighter down to 0.1mm – that's the width of a human hair. Our measuring capabilities by Vernier caliper allows us to observe ±0.03mm tolerances.

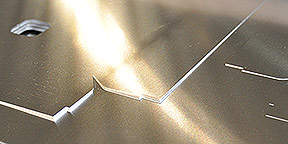

Precisely laser cut

Our laser cutting machines can load a 3 x 1.5m metal sheet and achieve ±0.01mm position repeatability right across the sheet. The fibre laser machines and control systems we cut with have only a 0.03mm beam kerf, which is 10x thinner than CO2 laser machines. They are also very quick (2.83m per second) which purposefully eliminates sheet metal heat distortion.

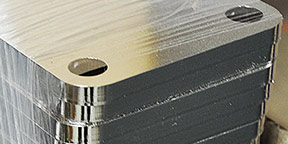

Bend and fold

Our bending and folding machines also have thickness detection and automatically adjusts the bend position to provide accurate and stable sheet metal bending. After each move the on-board DigiPro also checks the result, a highly accurate angle-measuring device that transmits back to the program to correct precise bend angles. These two processes ensure our bend and folds are within 0.25º accurate.

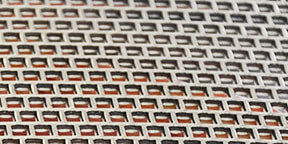

Fine-limit finishing

We have one of the best anodising departments in the UK in-house at Glenmore Hane, able to cope with any number of items up to approximately 2800mm long and 860mm deep/wide depending on the anodise type finish. From the thinnest 0.5µ Chromic anodising to the thickest 100µ Hard anodising, we can control to within 25µ based on the 720 Rule*. The aluminium anodising process provides us with another quality control check for material quality as the first etch process shows up faults or any sub-standards in aluminium material.

Other coatings including priming, adhesive, colour acrylic, synthetic, PSG, powder coated epoxy, polyester and epoxy polyester all come with their own thicknesses but we're able to control this within 0.1mm or so.

* The '720 Rule' states that it takes 720amp minutes per square foot to produce one mil of oxide.

1μ (micron) is 1000th of a millimetre (mm).

Final-limit

Whilst the average batch project will be within ±0.2mm as standard and down to ±0.1mm as required we can measure and monitor to within ±0.03mm of perfection. Our experience in the fine-limits of precision sheet metal fabrication and finishing covers a wide range scientific, pharmaceutical and medical equipment, environmental testing apparatus, aerospace and specialist automotive parts and components and all manner of precision engineering applications.

So whatever the brief to measure more accurately, react more neutrally, go higher, faster, be lighter, more stable, more airtight or handle more cleanly, Glenmore Hane can assist your quest at the cutting edge. With competence in complexity, excellence in precision and assuring quality, time and time again.

About us

Glenmore Hane remains committed to provide fine-limit sheet metal services by highly experienced and knowledgeable staff who can advise on test-proven production techniques as well as environmentally sound solutions. Specifically positioned on the M4 corridor with fantastic links across the UK. Glenmore Hane design, fabricate and finish high quality sheet metal components, fully qualified to work to ISO9001:2015 standards ensuring reliable and quality controlled production output on demand and on time. If you need precision sheet-metal prototypes or short run sheet metal fabrication and/or finishing – either send it direct through our website enquiry page, or contact Mark Hall on 01753 528884