Fabrication & Finishing for Space

1:30min reading timeWe have recently been involved in an exciting project – precisely fabricating and finishing parts for a planetary rover. It has a 350 million mile journey ahead through space at 55,000 miles per hour, when it gets there it'll rove about at 0.1 mph.

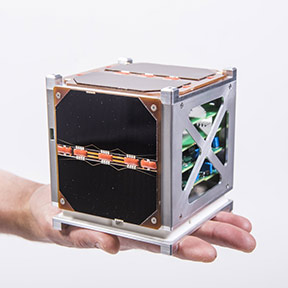

To make components that can survive the extreme conditions of space travel and the harsh environment you need high quality materials, precision and balance with acute attention to every detail. Our space destined parts are made possible due to our very tight 0.03mm beam kerf (with ± 0.01mm repeatability) laser cutting, our outstanding finishing department's perfect hard anodising of the 6061 and 7075 aluminium parts, and our quality control.

Space

There are many reasons to go to space, most in demand is TV broadcasting services throwing up satellites and dishes. Then there's geographic and weather observation satellites keeping an eye on our planet, overlooking natural occurrences and seeing if it'll rain or shine next week. Defence as you can imagine, is also very interested in the view from space perspective at the moment. Space X's Starlink is being used everywhere on expeditions, in residential homes, Teslas and on battlefields. Our future mobile phones look like they'll connect via a combination of towers and low-earth orbit satellites. Apple's iPhone 14 lineup already features basic satellite connectivity for SOS text messaging to emergency services and the Find My app can share your location, via satellite.

Space UK is a thriving industry, with 'value add' to the economy of £17.5 billion in 2020/21, and that during the pandemic. It's just the thing that works for the British mindset – engineering and boffin ingenuity.

Manufacturing

We are capable of manufacturing parts for all of the products mentioned – precise fabrication and finished components for here on earth and beyond. Be it specialist automotive, marine, aviation, pharma, medical or just some simple brackets, chassis or widgets. Finished raw, polished, primed, coated, powder-coated, painted or anodised. Dare we frame it as such but, we are literally out of this world!

Glenmore Hane – Earth HQ

We design, sheet fabricate and finish high quality metal components, and we can fold plastic here on earth. We are ISO9001:2015 management standards qualified ensuring reliable and quality controlled production on demand and on time. If you have a new project or existing production line, either send it direct through our website enquiry form, and/or call us and we'd be happy to take a sharp look at it.