Antimicrobial & antibacterial Anodising

Whilst we already offer antimicrobial powdercoating, we wondered what could be done with anodising. We have an excellent anodising plant here at Glenmore Hane (well proven for The Ventilator Challenge – 54,000 parts fabricated and finished) but we don't rest on our search for better.

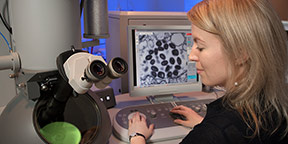

We can announce after a lengthy process of research and testing, anodised samples from Glenmore Hane passed ISO 22196 antimicrobial and bacterial tests with 99.2 – 99.4% efficacy.

"Given that the Glenmore Hane samples are tested for antimicrobial efficacy to the ISO 22196 test method, they will continue to reduce the grow of, and risk of cross contamination of harmful microbes and bacteria. The risk from MRSA and E.coli is still significant given the current situation and to those with compromised immune systems."

Independent Test Lab, October 2020

Sterilised surfaces

As the world fights the COVID-19 virus it's worth remembering the hygiene challenge at hand in hospitals, public- and work spaces where MRSA, E.coli, Legonella, Listeria, C-Difficile, Salmonella, Staphylococcus, and Pneumonia that can accumulate and seriously compound problems. A few years ago a control test was carried out in two classrooms, one had all the touch-point surfaces; tables, handles, push-plates, switches and chairs etc. antimicrobial and antibacterial coated, and the other retained standard fittings. After 1 year, the treated room demonstrated 95%+ less bacterial contamination and 20% reduction in illness and absenteeism by the users. Consider the significance of that in any work place, let alone in the NHS and private healthcare.

Helping your product-users reduce contagiousness, avoid sickness and be more healthy is clearly an important objective, making a product that does this demonstrates that integrity. We can't claim a Coronavirus cure but microbe and bacteria-free surfaces, then cleaned with 62-71% alcohol, does mean COVID-19 is destroyed.

"Viruses are actually fairly delicate bits of material, so they don't survive very long and the areas to focus on are smooth, flat, smooth plastic or metal surfaces."

Alex Akin, from the London School of Hygiene and Tropical Medicine.

Application and cost

All touchpoints such as handles, push-plates, work tops or switches obviously benefit by being treated, especially in healthcare, medical, pharmaceutical, food, aviation and hospitality industries. Expect the additional cost to be marginal over standard anodising prices and consider the saving made by not having to process an antimicrobial coating over the top.

To find out more…

Send your project details (inc. document uploads) directly via our website enquiry form, or enquire by telephone on 01753 528884