Glenmore Hane's polishing department provides the perfect polished metal service as well as graining and decorative surface finishes. Whilst polishing metal enhances appearances it also facilitates a practical purpose of removing surface defects and oxidation which prevents corrosion and as a result, extends component lifespan.

We provide a comprehensive range of metal polishing, buffing and graining specification finishes depending on what's required. Commonly, welding points are cleaned to an invisible finish and dressed for presentation, and components are prepared for anodising and electroplating. It takes highly skilled craftsperson to know exactly how to approach each task. It takes years of experience to know how much pressure and direction is required to universally grain or polish and not warp the shape or diminish the material. Maintaining form is paramount especially on thin and delicate sheet metal polished parts. The metal polishing process broadly starts with burnishing then pre-polishing, polishing and finishing. In more detail, it might involve a course 80 grit sanding through to 90, 120, 180, 240 or 320 grit which presents a fine brush finish. Polishing metal to 'mirror' or the ultimate 'super mirror' finish requires further processes with compound combinations on sisal mops, P175 WDR quality mops and fine buff tools. This is layer by layer metal polishing refinement to fine limit perfection.

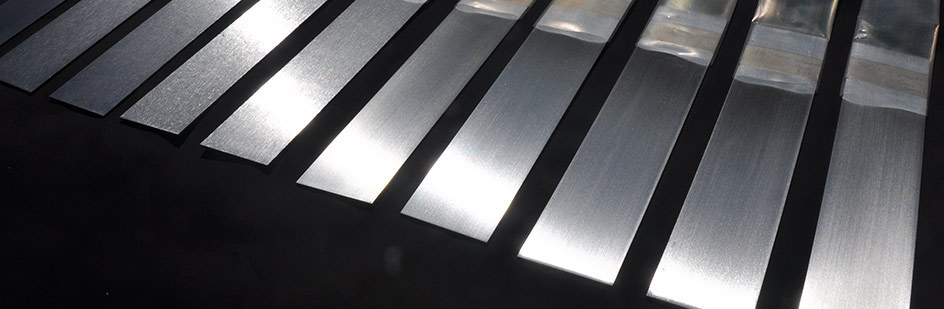

For some examples of Glenmore Hane's metal polishing finishes... click here (N.B. not to scale)

Just some of our metal finish methods are 251 method 1, 249, 10-01 (satin polish) and 217 for example. Metal surface decoration includes, non-directional graining, long grain, brushed metal, mirror and super mirror polished metal finishes. Understanding thin metal tolerances is paramount in conjunction with achieving the perfect finish without material depletion. Glenmore Hane stocks the correct compounds, specific mops and tools to ensure perfect metal finishes for every project.

The Glenmore Hane polishing room is a dust-free environment where our craftsmen polish, buff and grain items to client specifications. With Glenmore Hane sheet metal fabrication on site, we can further provide material quality and integrity assured in-house. Most importantly with machine or hand metal polishing and finishing it's our craftsmen's skill, knowledge and decades of honed experience that perfects the metal finish every time. We have sample plates of polishing finishes available to specify and ensure the exact finish required is achieved. Your specific graining pattern and metal finish can also be matched by sample before batch production. Glenmore Hane have polished metal components and grained items for pharmaceutical apparatus, medical equipment, automotive, aerospace and defence parts as well as interior design and architectural parts.